-

U.S. Dairy Exports Start with Farmer Passion for Sustainability, Customer Focus, Animal Care and Efficiency

By USDEC April 9, 2019- Tweet

First-person essays by four farmers show how the U.S. dairy industry lives its values for its global customers.

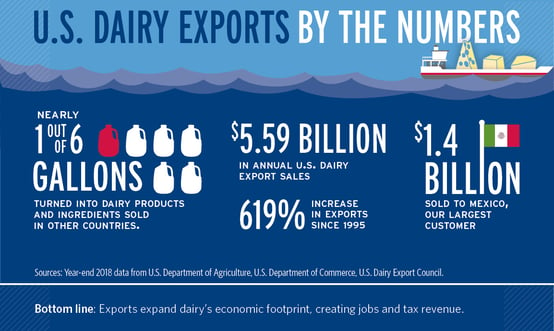

Despite the challenge of retaliatory tariffs from Mexico and China, the U.S. dairy industry set an all-time record for dairy exports last year, shipping more than 2 million tons of milk powders, cheese, butterfat, whey products, lactose and other products.

That added up to more than $5.5 billion in sales.

It all starts with an essential ingredient, milk, and a passionate person, the U.S. dairy farmer.

Below are first-person essays from four U.S. dairy farmers, each illustrating a value that has helped increase exports 619% in less than 25 years. Today, the milk from nearly one out of six tankers leaving American farms ends up in dairy products and ingredients enjoyed in other countries.

SUSTAINABILITY: Marilyn Hershey in Cochranville, Pennsylvania

Marilyn Hershey says sustainability means protecting the environment, and more.

Marilyn Hershey says sustainability means protecting the environment, and more.

There is a body of water in the eastern United States known as the Chesapeake Bay. The Bay is known for its beauty and is home to crabs, oysters and more than 300 species of fish.

I live a little north of there in Pennsylvania. The land is hilly and all the creeks and rivers flow toward the Chesapeake Bay. We have a creek running through our farm, so we work very hard to keep any runoff from the farm from reaching the creek. We want to protect the Bay!

We have installed stream-bank fencing that provides a buffer zone 25 feet on either side of the creek. Vegetation can grow wild there and absorb any water coming from the surrounding farm fields.

Rainwater that falls on the farm buildings — and the resulting runoff — is captured in pit. It is then pumped to another storage area, which keeps it confined and away from the creek.

Our farm is one of the 280 on-farm anaerobic digester systems in the United States. It benefits not just our farm, but the larger community by taking in potato waste from a local potato chip plant, as well as waste vegetable oil from restaurants. We mix those with manure in our manure digester. Methane is captured, which can be converted to electricity. We generate enough to power our farm and sell some of the surplus to a local utility company.

This anaerobic digester at Marilyn Hershey’s farm is an example of U.S. Dairy's commitment to sustainability. It generates electrical power from cow manure, waste from a local potato chip plant and vegetable oil waste from restaurants.

This anaerobic digester at Marilyn Hershey’s farm is an example of U.S. Dairy's commitment to sustainability. It generates electrical power from cow manure, waste from a local potato chip plant and vegetable oil waste from restaurants.

I am proud to be a dairy farmer. I love waking up early and seeing the sunrise. I love working around nature. I love working with the animals and caring for them. I get very attached to the animals.

We try to be as sustainable as possible, which means protecting the environment―and more!

CUSTOMER FOCUS: Brad Scott in San Jacinto, California

.jpg?width=831&name=Brad%20Scott4%20(3).jpg) Brad Scott, center, manages a 1,100-cow dairy farm with his brother, Bruce, and father, Stan. That milk is an essential ingredient in frozen yogurt sold around the world.

Brad Scott, center, manages a 1,100-cow dairy farm with his brother, Bruce, and father, Stan. That milk is an essential ingredient in frozen yogurt sold around the world.

I grew up on a farm in southern California. Besides the farm, our family had a creamery or processing facility. We sold milk to retail outlets in the state of California and later out of state. Going out of state was a big deal at the time, but today with international distribution it’s a whole new story.

We produce products for international frozen yogurt companies like Menchies, TCBY and Yogurtland, some of whom have locations here in Tokyo (or Hong Kong).

It’s exciting to walk into a Yogurtland in Tokyo knowing that the product being served may well have come from our farm. We are always happy to talk to the clerks and customers in the stores about the farm and the creamery.

Everything is done on our farm with the cow’s well-being in mind. Our cows eat our own feed grown from our own land in a warm comfortable climate year-round.

When the frozen yogurt companies visit our farm, I impress on them that we care for the cows seven days a week, 24 hours a day, 365 days a year. It is not a 9-to-5 job.

Often, the company representatives are surprised to see green fields on our farm, since they had the impression that we live in a dry area of the country. Their eyes get big when they see the green.

When customers visit Scott Brothers Dairy they are impressed by what they see, knowing that cared-for cows lead to cared-for customers.

When customers visit Scott Brothers Dairy they are impressed by what they see, knowing that cared-for cows lead to cared-for customers.

Cows offer unique contributions to food systems. The fields produce crops, most of which we cannot digest, to feed the cows. The cows make highly nutritious milk. The manure from the cows goes to fertilize the fields. And the cycle begins all over again.

The frozen yogurt companies are pleased to see the farm is sustainable, and they gain a new awareness that quality begins on the farm.

All the water on our farm is 100 percent recycled.

They are similarly impressed when they visit the creamery. They are impressed by the quality of the people, their friendliness, their knowledge and their commitment to quality.

ANIMAL CARE: Cheri Chapin in Remus, Michigan

On a recent trip to Japan and Hong Kong, Michigan dairy farmer Cheri Chapin enjoyed finding U.S. dairy products in supermarket dairy cases.

On a recent trip to Japan and Hong Kong, Michigan dairy farmer Cheri Chapin enjoyed finding U.S. dairy products in supermarket dairy cases.

We are always looking for ways to improve at our dairy, whether it is the way we feed or the way we keep our cows comfortable.Animal care is at the top of our priority list.

.png?width=554&name=Chapin%20(2).png) Fans and misters in the barns provide evaporative cooling, making it comfortable for Chapin's cows even on a hot day.

Fans and misters in the barns provide evaporative cooling, making it comfortable for Chapin's cows even on a hot day.

We keep close track of the animals’ health. Each of the cows wears a transponder around her neck which monitors her rumination and activity. If a cow’s rumination goes down, or she is not as active, it may an early warning sign of a health problem. We can check her temperature and see how she is doing.

A veterinarian comes out to check the cows every week, and a hoof trimmer comes to take care of the cows’ feet every two weeks.

We have good employees who are dedicated to animal care. They receive regular training, and we emphasize that the animals must be treated with respect. Before an employee is ever put in with the cows, he takes a training seminar and signs an agreement saying he will treat the animals humanely.

When visitors come to the farm, they comment that the animals are calm and appear to be well-cared-for. When it is 95 degrees outside, it’s interesting to

watch the visitors when they step into the barns and the fans and misters are going, providing evaporative cooling. The cows are eating, and the visitors can’t believe how comfortable they are.

watch the visitors when they step into the barns and the fans and misters are going, providing evaporative cooling. The cows are eating, and the visitors can’t believe how comfortable they are.Our annual rolling herd average is 31,740 pounds per cow, which is nearly 9,000 pounds above the national average. To achieve this, we must do many things well.

Cow care is one of them.

EFFICIENCY: Lowell Mueller in Hooper, Nebraska

Lowell Mueller keeps detailed records of his cows, their ancestry and their improvement over time.

Lowell Mueller keeps detailed records of his cows, their ancestry and their improvement over time.

It is estimated that 97 percent U.S. dairy farms are family-owned businesses. Like most farms our size, we must be efficient to stay in business.

We have switched from incandescent light bulbs to fluorescent in the barns and have found the fluorescents are four times more efficient than the old incandescent bulbs.

One area where we have really improved is manure management. We are using nutrients from the cows’ manure more efficiently than ever before.

We flush the barns with water to remove manure, and then the solids are separated out before the water goes to lagoons. Lagoon water is then applied to the fields to supply moisture and nutrients for crops. We have some fields where we have used very little commercial fertilizer the past 30 years, and we have been able to maintain above-average yields.

With the help of constantly improving technology and nutrition, the amount of milk produced per cow has almost doubled at Mueller's farm over the past 45 years.

With the help of constantly improving technology and nutrition, the amount of milk produced per cow has almost doubled at Mueller's farm over the past 45 years.

We also practice no-till on many of the fields, which means the soil is left undisturbed after a crop is harvested. Soil erosion is almost eliminated, and we have seen improvements in our soil conditions and yield because of it.

I handle the breeding program and am very proud of the progress we have made. We are a registered herd, which means we keep detailed records of our cows, their ancestry and how they have improved over time.

We believe our manure management system is a good example of sustainability. We are using our resources wisely to get more corn, alfalfa hay and soybeans from every acre and more milk from every cow.

The amount of milk we get from each cow, on average, has almost doubled since I began at the farm 45 years ago.

Mark O'Keefe is vice president of editorial services at the U.S. Dairy Export Council.

Learn more:

- 7 Things Farmers Need to Know About Their Investment in Exports

- Social Media Roundup of Dairy Farmers' Trip to Asia

- Farmers Take Dairy Checkoff Program's Global Vision to Japan, Hong Kong

- Skeptical Dairy Farmers Should Embrace Exports

- Why U.S. Dairy Exports Need "The Next 5%"

- Despite Tariffs from Mexico and China, 2018 U.S. Dairy Exports Reach Record High

- Blog posts from Marilyn Hershey,

- Got Dairy Jobs website with state fact sheets, videos and more.

- On social media, track dairy's important economic role with the #gotdairyjobs hashtag.

Subscribe to the U.S. Dairy Exporter Blog

The U.S. Dairy Export Council fosters collaborative industry partnerships with processors, trading companies and others to enhance global demand for U.S. dairy products and ingredients. USDEC is primarily supported by Dairy Management Inc. through the dairy farmer checkoff. How to republish this post.

10 Most Recent Posts

Most Popular Posts in Past Year

Index of Posts by Topic

- #GotDairyJobs (4)

- About USDEC (67)

- Africa (6)

- Australia (4)

- Blog (8)

- Brazil (4)

- Canada (20)

- Central America (1)

- Cheese (58)

- Chile (1)

- China (54)

- Common food names (7)

- Company News (20)

- Consistent Supply (1)

- Crisis Management (3)

- Cuba (2)

- Dairy (6)

- Dairy checkoff (9)

- Dairy Ingredients (5)

- Dairy Management Inc. (2)

- Dairy Resources (1)

- Dairy Supply Chain (1)

- Dairy Trends (5)

- Documentation (3)

- EU (24)

- Experts on Dairy Exports (4)

- Exporter of the Year (2)

- Exports (24)

- Farmer leaders (1)

- Farming (38)

- Food Aid (8)

- Food Safety (8)

- Foodservice (3)

- Free trade agreements (34)

- Future trends (1)

- Geographical Indications (GIs) (10)

- Global Marketing (86)

- Global Shipping Crisis (1)

- Got Jobs? (9)

- Indonesia (1)

- Innovation (17)

- Japan (17)

- Krysta Harden (1)

- Market Access (25)

- Market Conditions (271)

- Member Services (17)

- Mexico (41)

- Middle East (9)

- Middle East & North Africa (3)

- Middle East/North Africa (9)

- Milk (4)

- Milk Protein Concentrate (MPC) (2)

- New Zealand (11)

- Next5% (20)

- Nonfat Dry Milk/Skim Milk Powder (8)

- Nutrition (19)

- Product Innovation (6)

- Protein (4)

- Regulations (5)

- Research & Data (329)

- Russia (3)

- Singapore (10)

- South America (8)

- South Korea (10)

- Southeast Asia (25)

- Strategic Insights (1)

- Supply (1)

- Sustainability (26)

- Technology (2)

- ThinkUSADairy (5)

- TPM23 (1)

- TPP (13)

- Traceability (8)

- Trade Barriers (5)

- Trade Data (7)

- Trade Policy (72)

- TTIP (5)

- UHT Milk (7)

- USMCA (2)

- Vietnam (4)

- Whey (6)

- Whey Ingredients (2)

- Whey products (10)

- Whole Milk Powder (WMP) (3)

- World Dairy Expo (1)

- World Milk Day (1)

- Yogurt (1)

Index of Posts by Date, Author

- June 2021 (13)

- March 2015 (12)

- September 2015 (12)

- April 2015 (11)

- December 2015 (11)

- March 2014 (10)

- February 2015 (10)

- October 2015 (10)

- October 2014 (9)

- June 2015 (9)

- July 2015 (9)

- November 2015 (9)

- March 2016 (9)

- October 2019 (9)

- September 2013 (8)

- May 2015 (8)

- August 2015 (8)

- January 2016 (8)

- February 2016 (8)

- March 2017 (8)

- December 2018 (8)

- May 2019 (8)

- December 2019 (8)

- June 2014 (7)

- November 2016 (7)

- May 2017 (7)

- May 2018 (7)

- July 2020 (7)

- June 2023 (7)

- July 2016 (6)

- August 2018 (6)

- October 2018 (6)

- November 2018 (6)

- February 2019 (6)

- June 2019 (6)

- August 2019 (6)

- March 2020 (6)

- April 2020 (6)

- June 2020 (6)

- June 2022 (6)

- February 2014 (5)

- June 2016 (5)

- August 2016 (5)

- September 2016 (5)

- December 2016 (5)

- February 2017 (5)

- July 2017 (5)

- October 2017 (5)

- January 2018 (5)

- April 2018 (5)

- June 2018 (5)

- July 2018 (5)

- September 2018 (5)

- January 2019 (5)

- March 2019 (5)

- April 2019 (5)

- July 2019 (5)

- September 2019 (5)

- November 2019 (5)

- January 2020 (5)

- August 2020 (5)

- October 2020 (5)

- April 2021 (5)

- January 2022 (5)

- May 2013 (4)

- September 2014 (4)

- April 2016 (4)

- May 2016 (4)

- October 2016 (4)

- January 2017 (4)

- April 2017 (4)

- June 2017 (4)

- August 2017 (4)

- September 2017 (4)

- December 2017 (4)

- February 2018 (4)

- February 2020 (4)

- May 2020 (4)

- February 2022 (4)

- September 2022 (4)

- April 2023 (4)

- December 2023 (4)

- November 2017 (3)

- March 2018 (3)

- September 2020 (3)

- December 2020 (3)

- February 2021 (3)

- May 2021 (3)

- August 2021 (3)

- December 2021 (3)

- March 2022 (3)

- April 2022 (3)

- May 2022 (3)

- October 2022 (3)

- December 2022 (3)

- May 2023 (3)

- July 2023 (3)

- November 2023 (3)

- January 2026 (3)

- March 2011 (2)

- June 2011 (2)

- September 2011 (2)

- March 2012 (2)

- June 2012 (2)

- July 2012 (2)

- March 2013 (2)

- July 2013 (2)

- November 2020 (2)

- January 2021 (2)

- March 2021 (2)

- July 2021 (2)

- September 2021 (2)

- October 2021 (2)

- November 2021 (2)

- July 2022 (2)

- August 2022 (2)

- January 2023 (2)

- March 2023 (2)

- October 2023 (2)

- January 2024 (2)

- February 2024 (2)

- April 2024 (2)

- June 2024 (2)

- July 2024 (2)

- November 2024 (2)

- December 2024 (2)

- February 2025 (2)

- June 2025 (2)

- July 2025 (2)

- September 2025 (2)

- November 2025 (2)

- December 2025 (2)

- January 2010 (1)

- February 2010 (1)

- March 2010 (1)

- April 2010 (1)

- May 2010 (1)

- June 2010 (1)

- July 2010 (1)

- August 2010 (1)

- September 2010 (1)

- October 2010 (1)

- November 2010 (1)

- December 2010 (1)

- January 2011 (1)

- February 2011 (1)

- April 2011 (1)

- May 2011 (1)

- July 2011 (1)

- August 2011 (1)

- October 2011 (1)

- November 2011 (1)

- December 2011 (1)

- January 2012 (1)

- February 2012 (1)

- April 2012 (1)

- August 2012 (1)

- September 2012 (1)

- October 2012 (1)

- November 2012 (1)

- December 2012 (1)

- January 2013 (1)

- February 2013 (1)

- April 2013 (1)

- June 2013 (1)

- August 2013 (1)

- October 2013 (1)

- November 2013 (1)

- December 2013 (1)

- January 2014 (1)

- April 2014 (1)

- May 2014 (1)

- November 2022 (1)

- February 2023 (1)

- August 2023 (1)

- September 2023 (1)

- March 2024 (1)

- May 2024 (1)

- August 2024 (1)

- September 2024 (1)

- October 2024 (1)

- January 2025 (1)

- March 2025 (1)

- April 2025 (1)

- May 2025 (1)

- August 2025 (1)

- February 2026 (1)

- USDEC (183)

- USDEC Staff (167)

- Alan Levitt (119)

- Tom Suber (41)

- Margaret Speich (22)

- Marc A.H. Beck (15)

- Vikki Nicholson-West (11)

- Angélique Hollister (11)

- Tom Vilsack (8)

- Jaime Castaneda (7)

- Matt McKnight (7)

- Véronique Lagrange (7)

- Margaret Speich and Mark O'Keefe (7)

- Ross Christieson (7)

- Paul Rogers (6)

- Shawna Morris (5)

- William Loux (5)

- Alan Levitt and Marc Beck (5)

- Krysta Harden (4)

- USDEC Communications (3)

- Kristi Saitama (3)

- Marilyn Hershey (3)

- Brad Gehrke (3)

- Tom Quaife (2)

- Nick Gardner (2)

- Jim Mulhern (2)

- Alan Levitt and William Loux (2)

- Kara McDonald (2)

- Luke Waring (2)

- Merle McNeil (2)

- Krysta Harden, USDEC President and CEO (2)

- Andrei Mikhalevsky (1)

- Rodrigo Fernandez (1)

- Dermot Carey (1)

- Jeremy Travis (1)

- Annie Bienvenue (1)

- Ross Christieson and Shawna Morris (1)

- Becky Nyman (1)

- Paul Rogers and Tom Quaife (1)

- Rick Ortman (1)

- Tony Rice (1)

- Barbara O’Brien (1)

- Paul Rogers and Mark O'Keefe (1)

- Dalilah Ghazalay (1)

- Amy Wagner (1)

- Mitchell Bowling (1)

- Erica Louder (1)

- Brad Scott (1)

- Amy Foor (1)

- Scott Lantz (1)

- Sandra Benson (1)

- Errico Auricchio (1)

- Jaclyn Krymowski (1)

.png)