-

Chipotle's Stumbles Illustrate Gravity of Traceability

By USDEC March 16, 2016- Tweet

Commitments to follow traceability best practices now cover more than three-fourths of U.S. milk production.

Chipotle's “Food with Integrity” program only used suppliers that met its requirements for animal welfare, sustainability, and social accountability. "We do it," said Chipotle, "for farmers, animals, the environment, dentists, crane operators, ribbon dancers, magicians, cartographers and you."

But when Chipotle tried to locate the source of two separate E. coli outbreaks that sickened dozens of customers across several states last year, they couldn't do it, and are still paying for it. Lingering damage includes declining sales, a fallen stock price and a burrito-sized hit to the image of the Chipotle brand.

On Tuesday, Chipotle Mexican Grill Inc. said it would book its first quarterly loss as a public company. Restaurant sales dropped 26.1% in February.

Chipotle's difficulties illustrate how companies with sterling reputations can suddenly find their businesses threatened if they cannot quickly and successfully implement traceability protocols. Other food safety situations, such as the contaminated spinach crisis of 2006, show how one company's vulnerability can hurt an entire industry.

"When a food crisis goes global, the consequences can be even greater and the damage across cultures challenging to repair," says Margaret Speich, who oversees global crisis readiness as USDEC's senior vice president, strategic and industry communications. "Fast and conclusive traceability can slow or even stop a snowball before it starts rolling downhill, out of control."

U.S. Dairy industry best practices established

That's one of many reasons The Innovation Center for U.S. Dairy, established under the leadership of America's dairy farmers through the dairy checkoff program, has developed voluntary enhanced traceability best practices for dairy processors. When the best practices were released in 2013, five large processors, accounting for more than 20 percent of U.S. milk production, made the commitment to the protocols.

Since then, 21 more processors have committed to the guidelines, which now cover more than three-fourths of U.S. milk production.

“Traceability can protect and potentially increase your company’s bottom line," said Vikki Nicholson, senior vice president of global marketing at the U.S. Dairy Export Council, who worked with the The Innovation Center for U.S. Dairy to help develop the industry best practices. "The beauty of adopting enhanced traceability best practices is that it forces you to evaluate your business operations, which can lead to improvements in record-keeping, consistent lot Identification and inventory management, just to start.

"Traceability provides the ability to quickly identify if your products are included or excluded in a situation, determine which lots are involved, and where the product is within the supply chain. Timely, solid information like that can greatly minimize damage to your company’s brand and the broader U.S. dairy industry," she added.

According to the Centers for Disease Control, in the first Chipotle E.coli outbreak, 55 people were infected in 11 states. Twenty-one people were hospitalized. In the second, smaller outbreak, five people were infected with a different strain reported from three states. One ill person was hospitalized.

Chipotle and public health officials have been unable to identify a single food item or ingredient that could explain the outbreaks. The Centers for Disease Control issued the following statement:

"A review of Chipotle's distribution records by state and federal regulatory officials was unable to identify a single food item or ingredient that could explain illnesses in either outbreak. Food industries are an important partner in making food safer for everyone. They can help stop outbreaks and lessen their impact by keeping detailed records to allow faster tracing of individual shipments of foods from source to destination."

Even a false alarm can cause lingering damage

In 2013, a dairy processor in New Zealand was involved in a food-safety scare that underscored the importance of traceability. Thirty-eight metric tons of whey protein concentrate made by the Fonterra Co-operative Group were suspected to be contaminated with Clostridium botulinum. That led to recalls of infant formula in China, Vietnam and Saudi Arabia.

It proved to be a false alarm—the WPC was found to be clean—but the damage was already done. Fonterra’s inability to promptly and definitively track the destinations of the suspected batches of WPC escalated the problem, causing global markets to close.

Following that incident, New Zealand formed a working group to outline ways to upgrade the nation’s dairy traceability system.

"The Fonterra situation is a reminder we cannot rest on our laurels," Speich wrote in a 2015 U.S. Dairy Exporter post. "Anything can happen in today's highly competitive global environment where complex production and distribution channels are intrinsically linked, and rumors spread across continents in milliseconds."

Congress gets involved in Washington

In 2010, Congress passed the Food Safety Modernization Act, the most sweeping reform of food safety laws in more than 70 years. The law is meant to shift the focus from responding to food contamination problems to preventing them. Pilot studies have been completed, and now the Food and Drug Administration will provide a recommendation to Congress on the next steps to enhance traceability.

Cognizant of this, The Innovation Center for U.S. Dairy developed a voluntary program for dairy processors to guide them on the implementation of enhanced traceability. Processors with long-established traceability procedures can utilize the program to find potential gaps and make improvements.

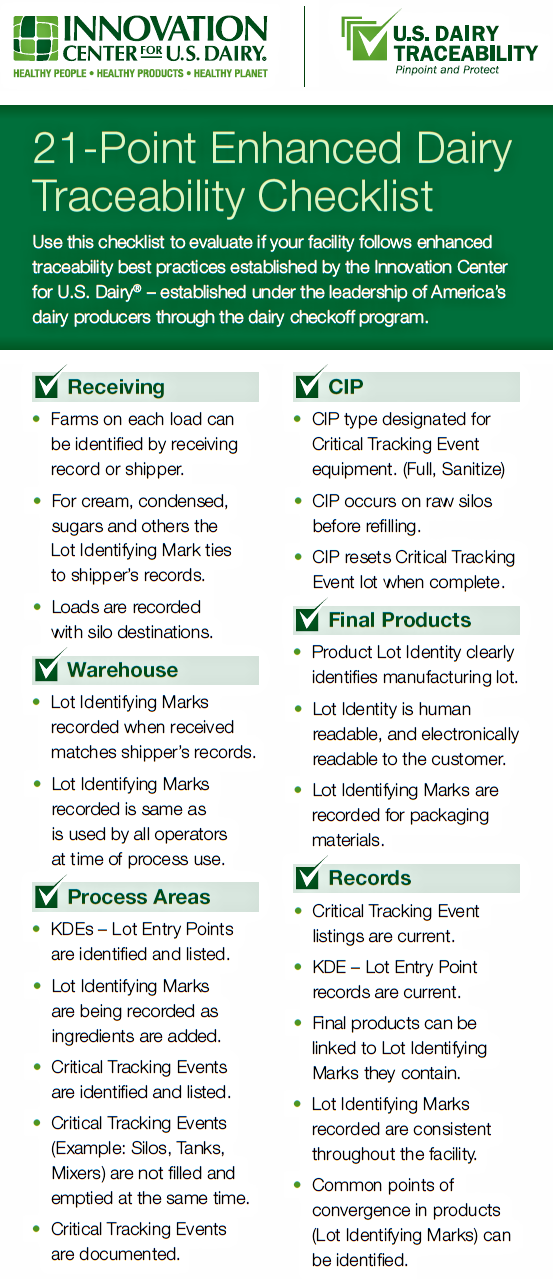

Practical resources to help dairy processors evaluate and implement enhanced traceability protocols can be found at dairytraceability.com. In addition, check out our concise, downloadable 21-point enhanced traceability checklist at the bottom of this page.

How one mid-sized processor employs traceability best practices

While most large processors were quick to commit to the voluntary guidelines, more small-to-mid-sized processors need to make the traceability commitment for the industry to reach its goal of having 80 percent of U.S. milk production covered.

One mid-sized dairy cooperative that has adopted a strong traceability initiative is Agri-Mark.

"Food safety has always been a vital initiative for our co

mpany, but traceability outside of our own walls requires standardization of processes and data," says Susan Zucker, supply chain director at Agri-Mark, a USDEC member company.

mpany, but traceability outside of our own walls requires standardization of processes and data," says Susan Zucker, supply chain director at Agri-Mark, a USDEC member company."In order to make sure that we are ready when our trading partners are, we need to stay on top of the industry initiatives and standards so we can implement business processes and systems that mirror these best practices."

The best practices established by The Innovation Center for U.S. Dairy have been invaluable.

"(They) provided a guideline for us as we reassessed our data structures for lot ID and product labeling. We need to make sure that this information can be captured electronically with bar codes as well as human readable for manual recording," Zucker says.

If a food safety issue occurs, governments in the United States and overseas expect fast action to isolate the problem and limit harm. There are no excuses.

"No matter what size your company is, customers and consumers are relying on your ability to be able to trace raw materials, ingredients and finished product throughout the supply chain," Zucker says. "Best practices and standards are crucial for transferring information about products that we need for traceability between trading partners."

Customers and consumers driving demand for traceability

Because food safety is an increasingly important issue to consumers around the world, knowing our industry is adopting enhanced traceability guidelines increases public confidence in U.S. dairy products and ingredients, both domestically and internationally.

"Customers and ultimately consumers are the driving force for enhanced traceability—more so than legislation—which is why the U.S. dairy industry continues to be committed to enhancing traceability practices across U.S. processors," Nicholson said.

Dairy processors with questions about making the industry's traceability commitment should check out the resources below. They can also email Vikki Nicholson at vnicholson@usdec.org or call at (703) 469-1522.

Additional Resources:

- Guidance for Dairy Product Enhanced Traceability (usdairy.com login required)

- Make the U.S. Dairy Traceability Commitment (usdairy.com login required)

- 17 U.S. Processors Make Enhanced Traceability Commitments as Industry Approaches 80 Percent (usdairy.com login required)

- Q&A: Crisis Management with Margaret Speich

- Fonterra Botulism Scare Shows Cost of Food Safety Crisis

- The Case for Dairy Traceability

- Traceability Can Boost Your Bottom Line in Global Marketplace

The 21-point traceability checklist for dairy processors(Download the PDF with a click here.)

Subscribe to the U.S. Dairy Exporter Blog

The U.S. Dairy Export Council fosters collaborative industry partnerships with processors, trading companies and others to enhance global demand for U.S. dairy products and ingredients. USDEC is primarily supported by Dairy Management Inc. through the dairy farmer checkoff. How to republish this post.

10 Most Recent Posts

Most Popular Posts in Past Year

Index of Posts by Topic

- #GotDairyJobs (4)

- About USDEC (65)

- Africa (5)

- Australia (4)

- Blog (8)

- Brazil (4)

- Canada (20)

- Central America (1)

- Cheese (58)

- Chile (1)

- China (54)

- Common food names (7)

- Company News (16)

- Consistent Supply (1)

- Crisis Management (3)

- Cuba (2)

- Dairy (6)

- Dairy checkoff (8)

- Dairy Ingredients (5)

- Dairy Management Inc. (2)

- Dairy Resources (1)

- Dairy Supply Chain (1)

- Dairy Trends (5)

- Documentation (3)

- EU (24)

- Experts on Dairy Exports (4)

- Exporter of the Year (2)

- Exports (24)

- Farming (38)

- Food Aid (8)

- Food Safety (8)

- Foodservice (3)

- Free trade agreements (34)

- Geographical Indications (GIs) (10)

- Global Marketing (87)

- Global Shipping Crisis (1)

- Got Jobs? (9)

- Indonesia (1)

- Innovation (17)

- Japan (17)

- Krysta Harden (1)

- Market Access (25)

- Market Conditions (248)

- Member Services (17)

- Mexico (40)

- Middle East (10)

- Middle East & North Africa (3)

- Middle East/North Africa (10)

- Milk (3)

- Milk Protein Concentrate (MPC) (2)

- New Zealand (11)

- Next5% (20)

- Nonfat Dry Milk/Skim Milk Powder (8)

- Nutrition (17)

- Product Innovation (6)

- Protein (4)

- Regulations (5)

- Research & Data (306)

- Russia (3)

- Singapore (10)

- South America (8)

- South Korea (10)

- Southeast Asia (25)

- Strategic Insights (1)

- Supply (1)

- Sustainability (25)

- Technology (2)

- ThinkUSADairy (5)

- TPM23 (1)

- TPP (13)

- Traceability (8)

- Trade Barriers (5)

- Trade Data (7)

- Trade Policy (72)

- TTIP (5)

- UHT Milk (7)

- USMCA (2)

- Vietnam (4)

- Whey (6)

- Whey Ingredients (2)

- Whey products (10)

- Whole Milk Powder (WMP) (3)

- World Dairy Expo (1)

- World Milk Day (1)

- Yogurt (1)

Index of Posts by Date, Author

- June 2021 (13)

- March 2015 (12)

- September 2015 (12)

- March 2014 (11)

- April 2015 (11)

- December 2015 (11)

- February 2015 (10)

- October 2015 (10)

- October 2014 (9)

- June 2015 (9)

- July 2015 (9)

- November 2015 (9)

- March 2016 (9)

- October 2019 (9)

- September 2013 (8)

- May 2015 (8)

- August 2015 (8)

- January 2016 (8)

- February 2016 (8)

- March 2017 (8)

- December 2018 (8)

- May 2019 (8)

- December 2019 (8)

- June 2014 (7)

- November 2016 (7)

- May 2017 (7)

- May 2018 (7)

- July 2020 (7)

- June 2023 (7)

- July 2016 (6)

- August 2018 (6)

- October 2018 (6)

- November 2018 (6)

- February 2019 (6)

- June 2019 (6)

- August 2019 (6)

- March 2020 (6)

- April 2020 (6)

- June 2020 (6)

- June 2022 (6)

- February 2014 (5)

- June 2016 (5)

- August 2016 (5)

- September 2016 (5)

- December 2016 (5)

- February 2017 (5)

- July 2017 (5)

- October 2017 (5)

- January 2018 (5)

- April 2018 (5)

- June 2018 (5)

- July 2018 (5)

- September 2018 (5)

- January 2019 (5)

- March 2019 (5)

- April 2019 (5)

- July 2019 (5)

- September 2019 (5)

- November 2019 (5)

- January 2020 (5)

- August 2020 (5)

- October 2020 (5)

- April 2021 (5)

- January 2022 (5)

- May 2013 (4)

- September 2014 (4)

- April 2016 (4)

- May 2016 (4)

- October 2016 (4)

- January 2017 (4)

- April 2017 (4)

- June 2017 (4)

- August 2017 (4)

- September 2017 (4)

- December 2017 (4)

- February 2018 (4)

- February 2020 (4)

- May 2020 (4)

- February 2022 (4)

- September 2022 (4)

- April 2023 (4)

- December 2023 (4)

- November 2017 (3)

- March 2018 (3)

- September 2020 (3)

- December 2020 (3)

- February 2021 (3)

- May 2021 (3)

- August 2021 (3)

- December 2021 (3)

- March 2022 (3)

- April 2022 (3)

- May 2022 (3)

- October 2022 (3)

- December 2022 (3)

- May 2023 (3)

- July 2023 (3)

- November 2023 (3)

- March 2011 (2)

- June 2011 (2)

- September 2011 (2)

- March 2012 (2)

- June 2012 (2)

- July 2012 (2)

- March 2013 (2)

- July 2013 (2)

- November 2020 (2)

- January 2021 (2)

- March 2021 (2)

- July 2021 (2)

- September 2021 (2)

- October 2021 (2)

- November 2021 (2)

- July 2022 (2)

- August 2022 (2)

- January 2023 (2)

- March 2023 (2)

- October 2023 (2)

- January 2024 (2)

- February 2024 (2)

- April 2024 (2)

- January 2010 (1)

- February 2010 (1)

- March 2010 (1)

- April 2010 (1)

- May 2010 (1)

- June 2010 (1)

- July 2010 (1)

- August 2010 (1)

- September 2010 (1)

- October 2010 (1)

- November 2010 (1)

- December 2010 (1)

- January 2011 (1)

- February 2011 (1)

- April 2011 (1)

- May 2011 (1)

- July 2011 (1)

- August 2011 (1)

- October 2011 (1)

- November 2011 (1)

- December 2011 (1)

- January 2012 (1)

- February 2012 (1)

- April 2012 (1)

- August 2012 (1)

- September 2012 (1)

- October 2012 (1)

- November 2012 (1)

- December 2012 (1)

- January 2013 (1)

- February 2013 (1)

- April 2013 (1)

- June 2013 (1)

- August 2013 (1)

- October 2013 (1)

- November 2013 (1)

- December 2013 (1)

- January 2014 (1)

- April 2014 (1)

- May 2014 (1)

- November 2022 (1)

- February 2023 (1)

- August 2023 (1)

- September 2023 (1)

- March 2024 (1)

- USDEC (183)

- USDEC Staff (140)

- Alan Levitt (119)

- Tom Suber (41)

- Margaret Speich (22)

- Marc A.H. Beck (15)

- Vikki Nicholson-West (11)

- Angélique Hollister (11)

- Tom Vilsack (8)

- Jaime Castaneda (7)

- Matt McKnight (7)

- Véronique Lagrange (7)

- Margaret Speich and Mark O'Keefe (7)

- Ross Christieson (7)

- Paul Rogers (6)

- Shawna Morris (5)

- William Loux (5)

- Alan Levitt and Marc Beck (5)

- Krysta Harden (4)

- USDEC Communications (3)

- Kristi Saitama (3)

- Marilyn Hershey (3)

- Brad Gehrke (3)

- Tom Quaife (2)

- Jim Mulhern (2)

- Alan Levitt and William Loux (2)

- Kara McDonald (2)

- Luke Waring (2)

- Merle McNeil (2)

- Andrei Mikhalevsky (1)

- Rodrigo Fernandez (1)

- Nick Gardner (1)

- Dermot Carey (1)

- Jeremy Travis (1)

- Annie Bienvenue (1)

- Ross Christieson and Shawna Morris (1)

- Paul Rogers and Tom Quaife (1)

- Rick Ortman (1)

- Tony Rice (1)

- Barbara O’Brien (1)

- Paul Rogers and Mark O'Keefe (1)

- Dalilah Ghazalay (1)

- Amy Wagner (1)

- Mitchell Bowling (1)

- Brad Scott (1)

- Amy Foor (1)

- Scott Lantz (1)

- Sandra Benson (1)

- Errico Auricchio (1)

- Jaclyn Krymowski (1)

.png)